PSD

In Photo-Stimulated desorption spectrometry (PSD) a sample is irradiated with by vacuum ultraviolet light at a wavelength of 120 to 400 nm.

The components desorbed from the outermost surface of the sample are detected with a mass spectrometer.

By sweeping the irradiation wavelength, it is possible to observe the differences between the desorbed components for each wavelength.

It can be used to analyze contaminants on the sample surface, the structure of the outermost surface of the sample, and the effects of vacuum ultraviolet light on the sample.

The heat assisted function enables observation of the photo-excited desorption phenomenon at a designated point.

This analysis is helpful in the design of heat and light processes used in semiconductors, displays and solar cells.

Load Lock Chamber

Instruments are equipped with a load lock chamber to improve the measurement efficiency and maintain a high vacuum environment without leakage to our analyzers.

Vacuum UV light source

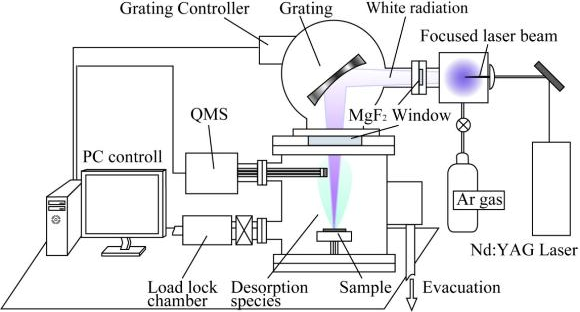

Generates light over a wide wavelength range, from visible to extreme ultraviolet, using laser excited plasma generated with argon gas and a Nd3+:YAG laser.

This light is separated by a diffraction grating, collected, and irradiated to the sample to cause desorption for each irradiation wavelength.

The wavelength sweep can be set from long to short wavelengths, or from short to long wavelengths.

Configuration

PSD consists of a VUV light source unit that generates vacuum ultraviolet light, and a measurement unit that detects the components that are desorbed from the sample.

Structure of the PSD analyzer

VUV light source

When an Nd3+:YAG laser beam is introduced into a light source chamber filled with argon gas, the argon gas is excited and plasma is generated. This laser-excited plasma emits light across a wide wavelength range, from vacuum ultraviolet to the visible region. Desorption at each irradiation wavelength is observed by irradiating the sample with monochromatic light separated using diffraction gratings. The available wavelengths are determined by the installed diffraction grating. The standard for this device is 120 to 400 nm.

Loadlock chamber

The load-lock chamber is essential for achieving high sensitivity and high-efficiency (high throughput) measurement. Our load-lock chamber and sample transfer mechanism enable quick insertion of only the sample into the analysis chamber under an ultra-high vacuum.

If there is no load-lock chamber, it is necessary to expose the analysis chamber to ordinary atmosphere each time the sample is exchanged. A large amount of air (mainly water) is drawn into the analysis chamber when it is exposed to ordinary atmosphere, making it necessary to perform evacuation for a long time to return to a suitable vacuum level.

Analysis chamber

Photo-stimulated desorption induced by vacuum ultraviolet irradiation is promoted by raising the temperature. Applying our TDS technology, vacuum UV irradiation can be performed while holding the sample at a constant temperature.

The analysis chamber has the same configuration as a temperature-controlled desorption analyzer. Samples can be heated with minimal increase in background level even at high temperatures. The spectroscopic chamber of the vacuum ultraviolet light source section and the analysis chamber of the measurement section are connected by an MgF2 flange with a window.

| Surface analysis of organic materials | Photo-Stimulated Ds-Extreme top surface organic matter analysis ※Japanese PDF file opens. |

|---|---|

| Principle | Principle of Photo-Stimulated desorption |

| Acquisition data example | Acquisition data example (PMMA) Acquisition data example (PET) |