A mechanism to purge the load lock chamber without scattering a powder sample.

Menu

The infrared heating type temperature-controlled thermal desorption analyzer TDS1200Ⅱ is an analyzer that utilizes a spectrometer to provide real-time observation of the molecules desorbed during the programmed temperature control of the sample in an ultra-high vacuum.

Components with high background levels, like water, hydrogen, oxygen and carbon dioxide, can be detected, even in trace amounts, because the measurements are performed in a vacuum.

The chemical species can be identified and quantified for the molecules desorbed from the sample. Information like the absorption/bonding state and diffusion process of the desorbed gas can also be obtained.

Suitable for measurements in which infrared heating is easy to perform, such as thin film samples and samples with a thin sheet form. The new TDS1200II incorporates a renewed version of the TDS1200 system and a touch panel interface. Satisfies the standards for CE marking.

The loadlock chamber is essential for achieving high sensitivity and high-efficiency (high throughput) measurement. Our load-lock chamber and sample transfer mechanism enable quick insertion of only the sample into the analysis chamber under an ultra-high vacuum.

If there is no load-lock chamber, it is necessary to expose the analysis chamber to ordinary atmosphere each time the sample is exchanged. A large amount of air (mainly water) is drawn into the analysis chamber when it is exposed to ordinary atmosphere, making it necessary to perform evacuation for a long time to return to a suitable vacuum level.

For thermal desorption analysis it is important not to heat the analysis chamber or parts inside the analysis chamber when the sample is heated. If the chamber is heated during TDS it is difficult to distinguish between the gases desorbed from the sample and the gases desorbed from the chamber.

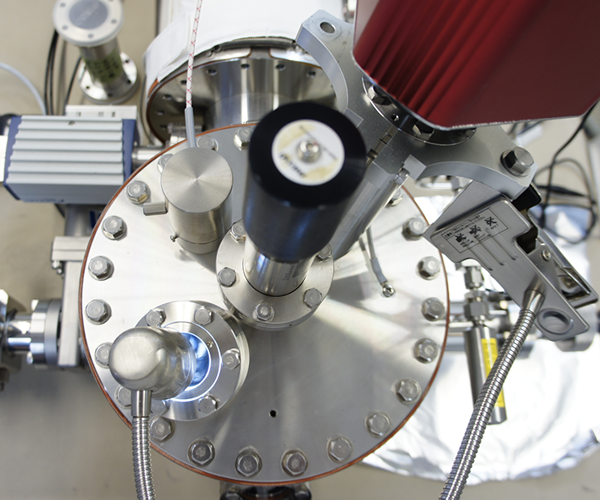

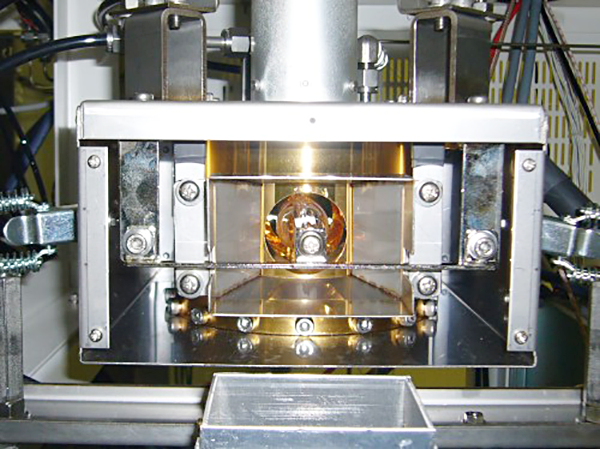

TDS1200II directly heats the sample with infrared radiation introduced via a quartz rod, enabling increases in the background level to be suppressed, even in the high temperature range, providing high-sensitivity measurement.

To detect the desorbed gases with high sensitivity, a QMS ionization chamber is placed directly above the sample. The position directly above the sample allows the gases desorbed from the sample to reach the QMS ionization chamber directly, enabling highly sensitive detection of even materials like metals that become easily deposited and organic molecules with a high molecular weight.

The data processing program enables quantitative analysis of the desorbed gases. To perform quantitative analysis of the desorbed gases, it is necessary to regularly calibrate the sensitivity of the mass spectrometer.

Sensitivity calibration using standard leaks requires preparation of an expensive standard leak for each type of gas, and the calibration procedure is time-consuming. In addition, strict health and safety management is required when standard leaks of poisonous gases are used.

The current quantification program enables quicker, easier, and safer quantitative analysis of the desorbed gases than the method using calibration with standard leaks. Highly accurate results can be obtained simply by periodically measuring the NIST-traceable hydrogen standard sample produced by ESCO. The sensitivity correction method we have developed can correct the sensitivity even for gases other than hydrogen, and it has been verified that the results obtained are in good agreement with quantitative results obtained using calibration with a standard leak according to the National Institute of Advanced Industrial Science and Technology (AIST) standards.

Japanese Only

昇温脱離法の解析に使用される脱離モデルや活性化エネルギの求め方についての参考資料です。

※Japanese PDF file opens.

Japanese Only

この資料は平下・内山の分析化学での報告 「N.Hirashita and T.Uchiyama, BUNSEKI KAGAKU, 43 , 757 (1994)」に基づいています。

昇温脱離分析装置で測定した昇温脱離スペクトルから、脱離ガスの定量を行うことができます。

測定チャンバーの排気速度が脱離ガスに起因する測定チャンバーの圧力変化に比べて十分に大きいとき、脱離ガスの分圧の変化は単位時間あたりの脱離量(脱離速度)に比例します。

質量分析計ではイオン電流と分圧は比例するので、結局イオン電流と脱離速度が比例することとなり、イオン電流を積分した面積強度から全脱離量を計算することができます。

既知量のH+を注入したSi試料を用いて面積強度と脱離量の比例係数を求めておけば、様々な試料についてm/z2の面積強度から水素の脱離量を決定することができます。

また水素以外の分子については、水素と目的分子のイオン化難易度、フラグメンテーションファクター、透過率などのパラメーターから目的分子についての比例係数を計算することができます。 この比例係数を使えば水素以外の分子の定量も可能です。

※Japanese PDF file opens.

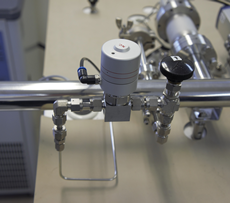

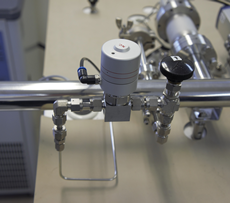

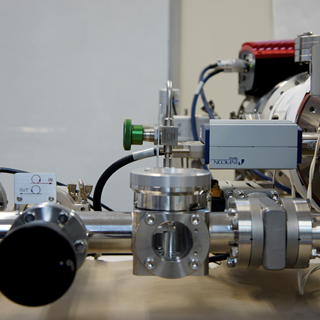

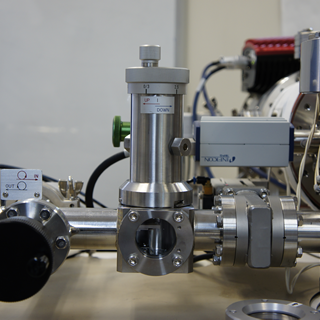

A mechanism to purge the load lock chamber without scattering a powder sample.

| Purpose | ・If the load lock chamber is purged normally when a powder sample is inserted, the sample will be scattered. ・Switch type valve is adopted for the purge line. ・Easy to operate and eliminates the scattering of powder samples. |

|---|---|

| Composition | Slow leak valve ASSY(SUS piping, needle valve and others) |

| Applicable instruments | ・TDS1200Ⅱ ・TDS1200 ・EMD-WA1000S/W ・EMD-WA1000S |

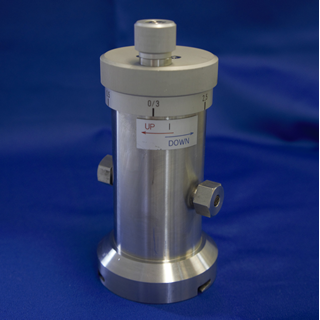

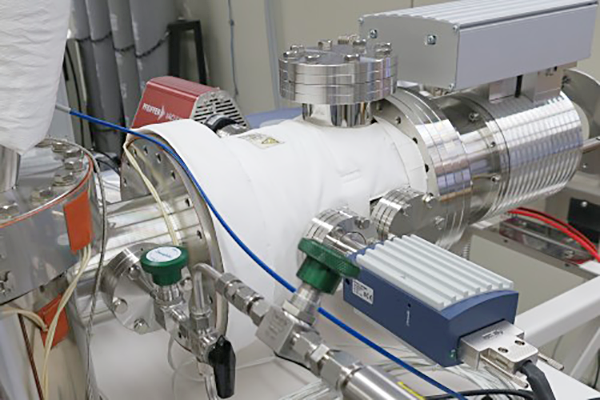

A mechanism to load the TDS sample prepared in a controlled environment such as a glove box into the TDS load lock chamber without exposure to the atmosphere.

| Specification | Outside air exchange speed=1.5MPa→1.5MPa (48h later) |

|---|---|

| Composition | ・Transfer vessel(Pressure gauge also available) ・Load lock chamber for transfer vessel mounting |

| Applicable instruments | ・TDS1200Ⅱ ・TDS1200 ・EMD-WA1000S/W ・EMD-WA1000S |

| Other | Parts can be purchased separately When attached to TDS, it is necessary to modify the load lock mechanism. |

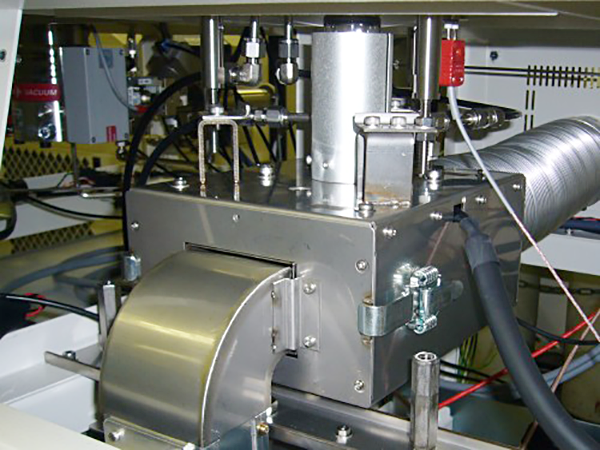

The transparent stage and the SiC stage can be easily exchanged to suit the heating conditions.

If a sample stage becomes contaminated by sample sublimation, it can be immediately exchanged, enhancing safety.

Cooling water circulation is required to cool the IR mirror.

If there is no cooling water supply facility at the installation environment, it is recommended to use a cooling water circulation system with the instrument.

You can select from a single function cooling water circulation system, to a variety of optional function mounted types.

Combined with the leak sensor, it can also be used to turn off the cooling water circulation system, and turn off the infrared heating, etc. when a leak is detected.

Reduces the deposition of metal onto the test tube to help prevent deterioration of QMS sensitivity.

By installing a liquid nitrogen trap it is also possible to determine the hydrogen content in steel with even higher accuracy.

The standard heating to 1200 ℃ can be raised to 1400 ℃.

| Standard sample | Hydrogen ion implantation standard sample | |||

|---|---|---|---|---|

| F-remover | F-remover | |||

| Stage | SiC sintered sample stage | Circular transparent sample stage | ||

| Sample plate | Transparent quartz sample plate [AM100749-4] |

Transparent quartz sample plate-C [ES001461-4]

|

SiC sintered sample tray [ES000036-4] |

|

| Heating lamp | 1kW Heating lamp | 2kW Heating lamp | ||

Copyright© ESCO, Ltd.All Rights Reserved. login